Interview– Amal Charles, Trumpf

Watch the full episode :

Trumpf’s Climate Action Strategy 2030

Under its “Climate Action Strategy 2030,” Trumpf has laid out a comprehensive plan to reduce greenhouse gas and carbon dioxide emissions. “Established in 2017, this strategy is our roadmap to align with the Paris Climate Agreement,” Charles notes. This ambitious plan is not just a commitment on paper but is actively influencing every aspect of Trumpf’s product development and internal processes.

With a diverse portfolio ranging from machine tools to laser technology and additive manufacturing machines, Trumpf is uniquely positioned to implement sustainable practices. “We produce serial parts for our machines internally and are constantly analyzing our carbon footprint,” Charles says. He highlights the redesign and optimization of a motor cooler, traditionally manufactured with various components from different suppliers, which has now been 3D printed on the TruPrint 3000. This innovation has led to an 80% reduction in carbon dioxide emissions for this part.

Redesigned and optimized motor cooler, traditionally manufactured with various components from different suppliers, which has now been 3D printed on the TruPrint 3000. This innovation has led to an 80% reduction in carbon dioxide emissions for this part.

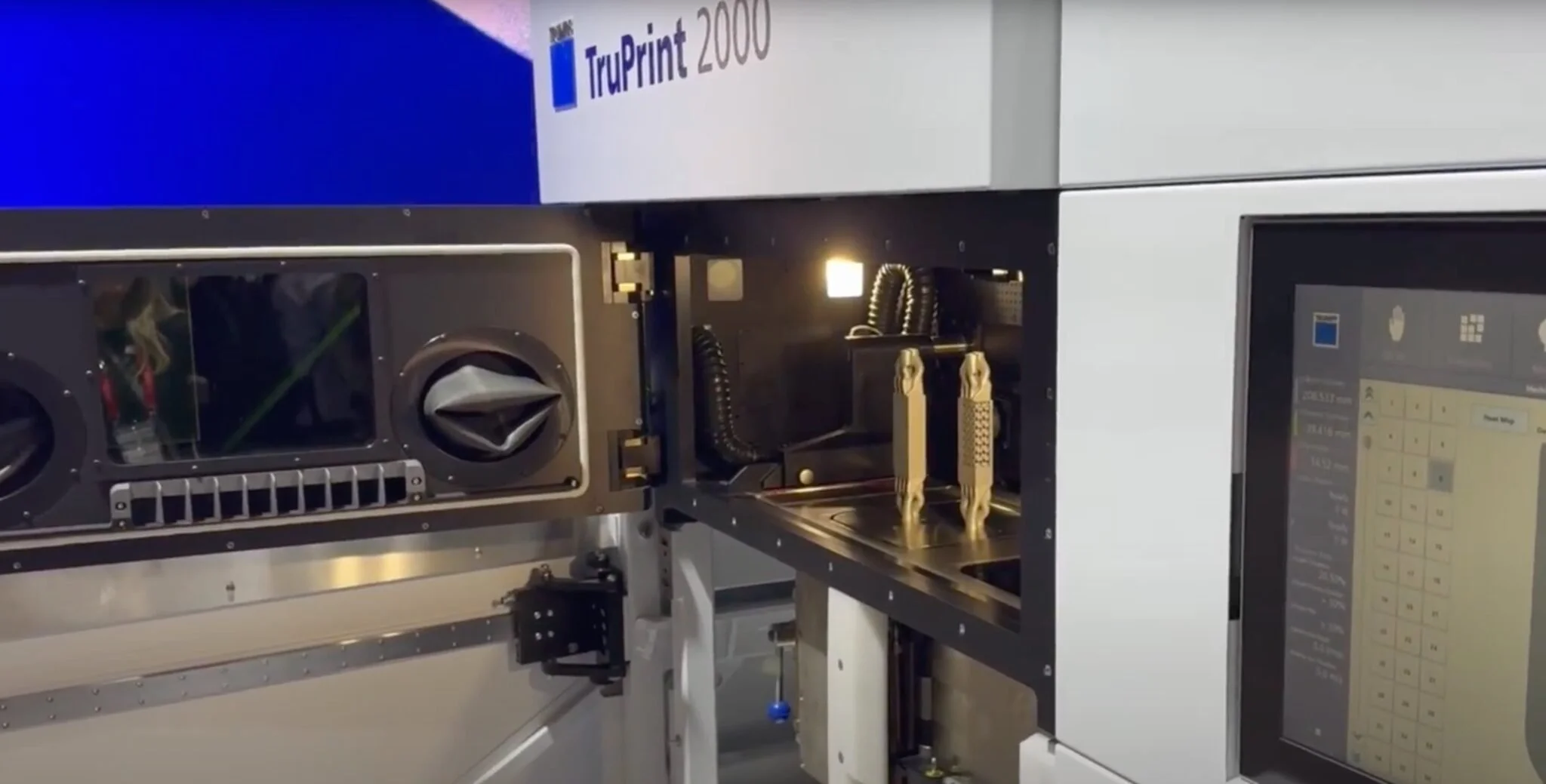

The introduction of the TruPrint 2000 is a testament to the Trumpf commitment to sustainable innovation. “While increasing the build volume and laser power of the TruPrint 2000, we’ve maintained the same energy consumption, effectively halving the energy consumption per part,” Charles explains. This is a significant achievement, demonstrating how Trumpf balances technological advancement with environmental responsibility.

TruPrint 2000 boasts larger build volume and throughput, with the same energy consumption as the previous model.

Integrating Sustainability Across Business Practices

For Trumpf being sustainable is not a separate initiative but an integral part of its business model. “Every new feature or product now focuses on reducing energy consumption,” Charles states. This includes improvements in well-plug efficiency in lasers and revamped filter systems in new machines. These incremental improvements are designed to have a substantial impact on the environmental footprint of their customers, who use Trumpf’s machines for part production.

Trumpf’s century-long legacy is now strongly aligned with a commitment to sustainability, showcasing how traditional industries can adapt and contribute positively to environmental challenges. Amal Charles’s insights reflect the company’s dedication to reducing the environmental impact of its products and supporting its customers in their sustainability goals.